SHELL AND TUBE HEAT EXCHANGERS

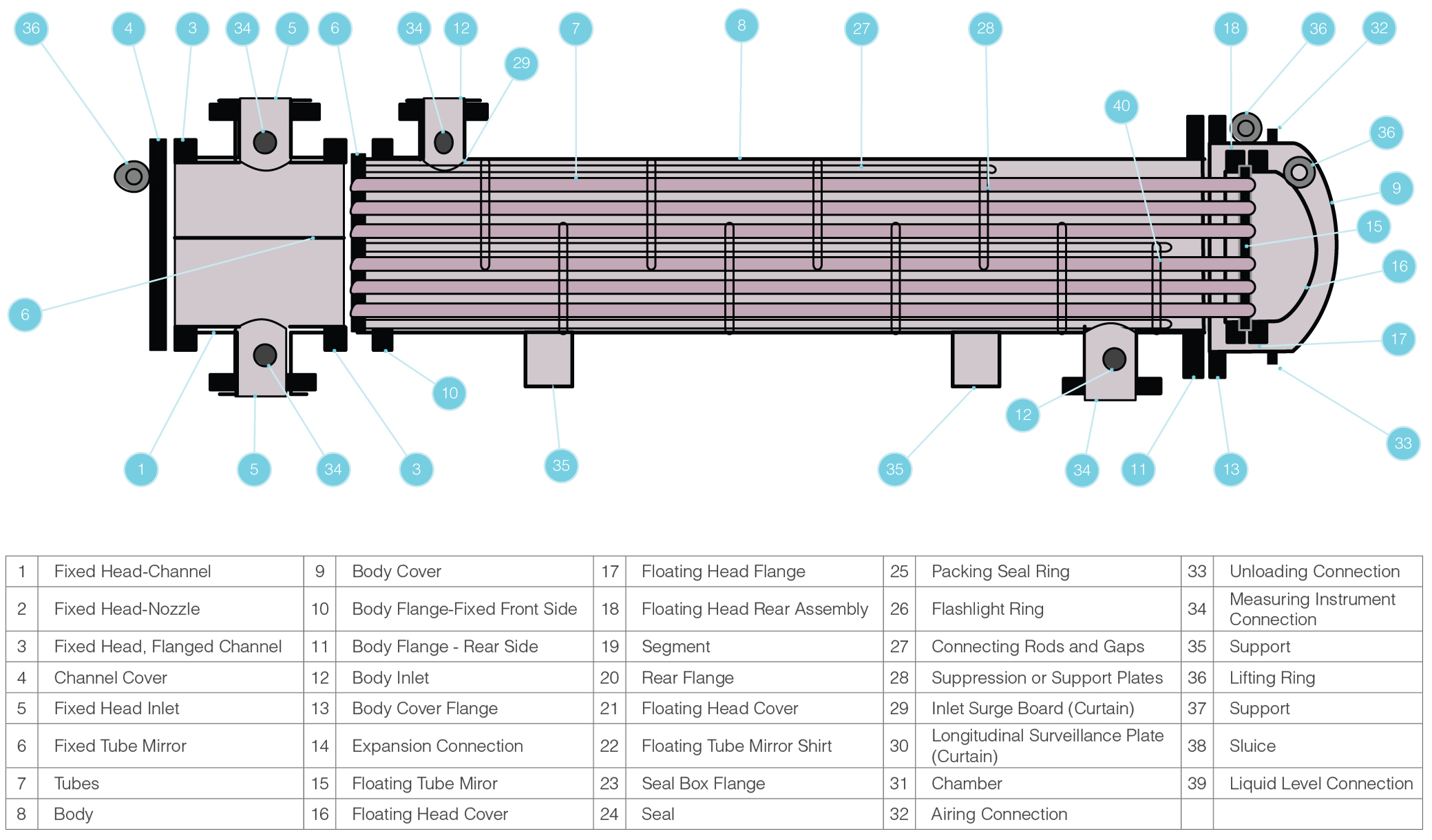

Components of Tube Heat Exchangers

Tube Heat Exchanger is a class of heat exchanger designs used in all processes. It has several variations within its own group.

It is the most widely used heat exchanger in industrial facilities such as iron and steel, petroleum, petrochemical, gas, power plants, food, pharmaceuticals, leather, textiles, air conditioning, ships and maritime sectors.

The heat exchangers used in the industries can be used in all sectors where there is a second alternative energy requirement from an alternative energy.

In tube heat exchangers, heat transfer surface consists of tubes.

While one fluid runs through the tubes, other fluid flows outside the tubes but inside the shell as parallel or across the tubes. So, heat is transferred over tube surfaces.

Components of Tube Heat Exchangers

- Straight or U bend tubes enabling heat transfer

- Shell manufactured from tube or bent plate

- Face plate or face plates by which the tubes are fixed

- Baffles directing the flow outside the tube but inside the shell and supporting the tubes

- Nozzles enabling the exit and entrance of shell side fluid

- Head and Head Nozzles enabling the exit and entrance of tube side fluid

- Flanges that detect mirror and heads

- Carrying legs enabling the assembly of heat exchanger on any base

- Isolation preventing heat loss from the outer surfaces of heat exchanger

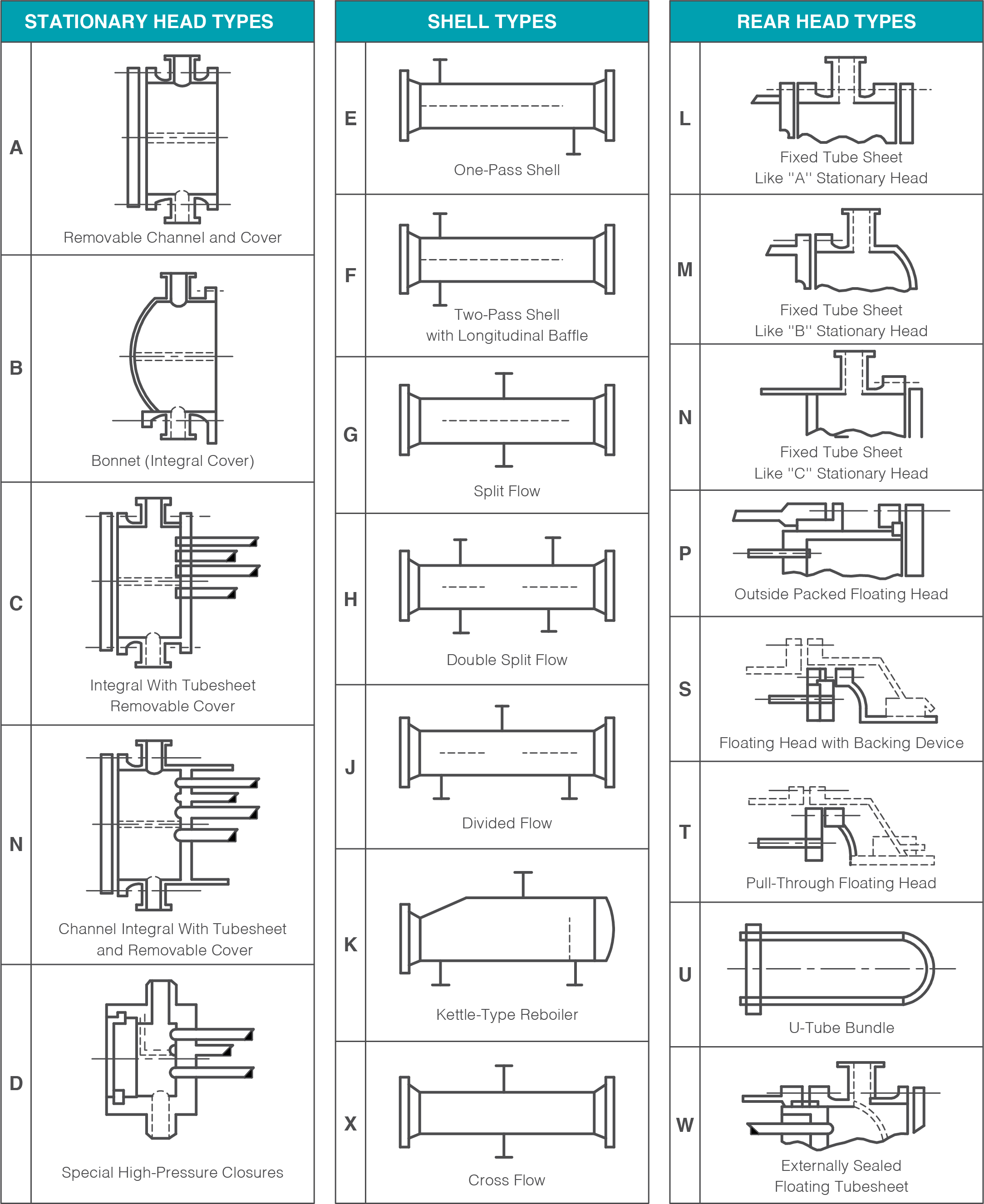

TEMA Type Heat Exchangers

FOLLOW US ON FACEBOOK!

Be fan of our official Facebook fan page and development of the first to get your news!

Contents of Professional Service Package:

- Plate supply for every brand and model.

- Gasket supply for every brand and model.

- Revision and cleaning of plate heat exchanger.

- Fast and detailed cleaning of heat exchanger plates.

- Cleaning heat exchanger plates with special chemicals.

- Production and supply of every type of nut and pin.

- Delivery of heat exchanger operating like it is new.

- 7 days 24 hours service opportunity.