THERMOREGULATOR

What is Thermoregulator?

The word "thermoregulator" consists of the combination of the words "thermal" and "regulator" and they regulate the heat as the name suggests.

Thermoregulators are used as tools that provide the necessary sensitivity, especially in applications where temperature must be adjusted very specifically, such as mold cooling and heating processes. In the mold industry, high-quality products can only be obtained thanks to this sensitivity. The thermoregulators developed by MIT engineers are also designed to be able to perform precise heating and cooling gradually.

There are many different mold techniques and thermoregulators are used as heat regulators in all of them. For example, the mold temperature needed in plastic injection machines is different during and after filling. The mold should be cold during filling. So that the high temperature liquid does not freeze or deteriorate structurally while filling the mold. But after it is filled, mold should be cold to solidify the product in optimum time. For this reason, MIT Thermoregulators (heat regulators) are often used in plastic injection machines to ensure thermal stability.

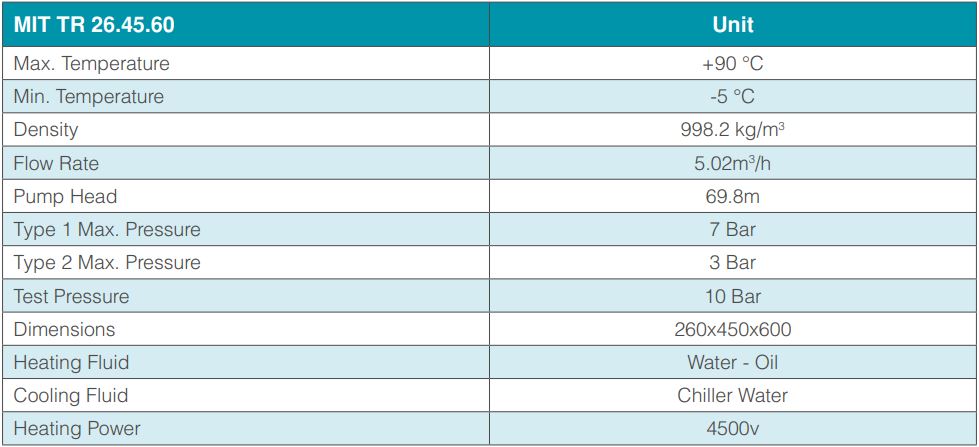

It is essential to use a quality thermoregulator to produce quality products with plastic mold injection. In order for the plastic in liquid form to remain liquid, it needs a stable heat balance and then it needs to be cooled quickly to freeze. It is almost impossible to fulfill these two conditions without using a thermoregulator. MIT Thermoregulators provide this optimization with heating elements in the heating section and cooling water from the chiller in the cooling section. In cases where cooling water cannot be provided, complete cooling systems with MIT products that complement the thermoregulator are installed. Thanks to this working principle, efficiency increases, energy consumption decreases, time is saved, and most importantly production capacity increases.

Features and Advantages of MIT Thermoregulator

- Complete product production

- High quality surfaces and low material loss

- Low internal stresses and high resistance

- Getting rid of post-mold processes (deburring, painting etc.)

- Shortening cycle time and increasing production

- Energy consumption reduction

Call Now

Request a Quote

Download Catalog

View Catalog

Call Now

Request a Quote

Download Catalog

View Catalog

FOLLOW US ON FACEBOOK!

Be fan of our official Facebook fan page and development of the first to get your news!

Contents of Professional Service Package:

- Plate supply for every brand and model.

- Gasket supply for every brand and model.

- Revision and cleaning of plate heat exchanger.

- Fast and detailed cleaning of heat exchanger plates.

- Cleaning heat exchanger plates with special chemicals.

- Production and supply of every type of nut and pin.

- Delivery of heat exchanger operating like it is new.

- 7 days 24 hours service opportunity.