Stainless Steel Tanks

Stainless Steel Tanks

EKiN ENDÜSTRiYEL serves food, chemical,residental and hotel sectors with producing stainless steel tanks which are designed by our professional engineers.

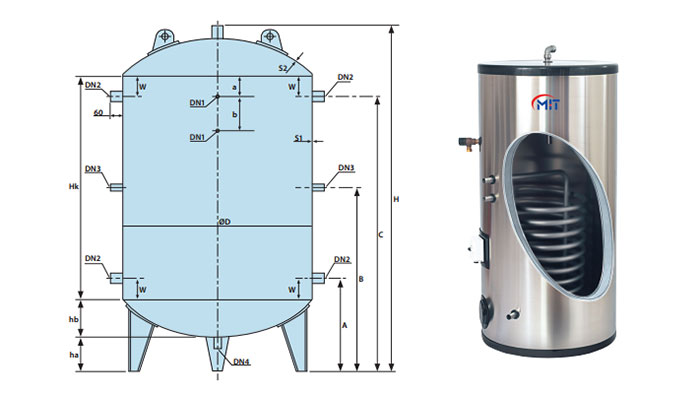

Stainless steel tanks are usually used in food, industrial plants and hotels for potable water. Stainless steel tanks must be designed according to required specifications before producing.

Those specifications are.

- Operating temperature and pressure

- Dimensions

- Material

- Nozzle (Ball shaped nozzle, Ellipsoid nozzle, Conical part, Torispherical nozzle)

- Pipe connection diameter and pressure class

- Climate (wind,earthquake and ground specs.)

Some of the liquids will show different physical and chemical reactions at various or escalated temperatures. Therefore, the medium of operating temperature must be provided in order to produce stainless steel tanks with right materials. Our experts and well experienced engineers in EKiN Industrial, are able to design and produce stainless steel tanks with right materials according to the liquid type. Material thicknesses are identified according to operating pressure(s) and total volume of tanks.

While producing stainless steel tanks, the most important operation is welding. Capillary cracks and undercuts are the most common mistakes. Capillary cracks must be checked with radiographic tests.If not checked, capillary cracks may lead to very serious problems in the future because of continuous exposal to pressure.Therefore, the welder must be very experienced and properly certified. EKiN INDUSTRIAL BV has certified welders to to get the job done in the right way.

EKiN INDUSTRIAL can produce stainless steel tanks, from 100 lt to 5000 lt with AISI 304, AISI 316, AISI316Ti. If required, any certificate (worldwide) can be gathered for our tanks.

Advantages of stainless steel tanks compared to other tanks:

* High resistance to corrosion.

* Lasts longer than other tanks.

* Can be used in acid and corrosive applications.

* Hygienic

Nowadays, many illnesses are caused by lack of hygiene. Galvanized and enamelled tanks which are over 1000 l, might have air bubbles in their chambers that can not be covered causing corrosion. On long term, the corrosion will deform the tank and destroy it.

Call Now Request a Quote Download Catalog View Catalog

FOLLOW US ON FACEBOOK!

Be fan of our official Facebook fan page and development of the first to get your news!

Contents of Professional Service Package:

- Plate supply for every brand and model.

- Gasket supply for every brand and model.

- Revision and cleaning of plate heat exchanger.

- Fast and detailed cleaning of heat exchanger plates.

- Cleaning heat exchanger plates with special chemicals.

- Production and supply of every type of nut and pin.

- Delivery of heat exchanger operating like it is new.

- 7 days 24 hours service opportunity.