Eco Neutralization Tanks

Eco Neutralization Tanks

Neutralization units are devices that neutralize the condensed water formed in condensing systems. Failure to neutralize these acidic wastewaters before going to the mains or drains may cause serious damage to the plumbing system. Therefore, in cases where the wastewater exceeds acceptable acidic values, neutralization tanks are used in order to neutralize these waters to meets the discharge values determined by the regulations.

How Neutralization Tank Works?

The most commonly used method in the neutralization process is to bring acidic chemical waste into contact with limestone (calcium carbonate). Thanks to the limestones in the chambers inside the neutralization tank, the liquid entering the tank at a very acidic level, such as pH 3, exits the tank with neutral pH values of 5.5-8.5.

Neutralization Tanks Fields of Application

- Condensing systems

- Acid wastewater producing processes

- Battery storage areas

- Laboratories

MIT Neutralization Tank Features

- Tank material is PP or HDPE

- Complies with the legislation

- Easy to install and use

- It is easy to maintain and clean

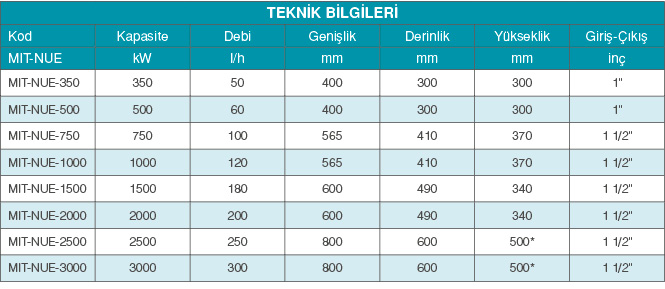

- It can be manufactured in different sizes and capacities.

- It is an affordable and effective system.

- Cover bolts are stainless steel.

- Tank content includes limestone and neutralization granules.

Things to be Considered While Operating Neutralization Tanks

- Limestone in the tank should contain more than 90% calcium carbonate.

- pH value should be measured periodically, and if the pH value is low, limestone should be added.

- The salt released as calcium carbonate decreases is ineffective in the chemical reaction and forms sludge in the tank. This sludge must be discharged to prevent it from interrupting liquid flow and chemical reaction.

Compliance and Quality

The quality of the neutralization units produced by Ekin Endüstriyel are compliant with the following certifications.

- CE

- ISO 9001

FOLLOW US ON FACEBOOK!

Be fan of our official Facebook fan page and development of the first to get your news!

Contents of Professional Service Package:

- Plate supply for every brand and model.

- Gasket supply for every brand and model.

- Revision and cleaning of plate heat exchanger.

- Fast and detailed cleaning of heat exchanger plates.

- Cleaning heat exchanger plates with special chemicals.

- Production and supply of every type of nut and pin.

- Delivery of heat exchanger operating like it is new.

- 7 days 24 hours service opportunity.