HOMOGENIZER

What Is Homogenizer?

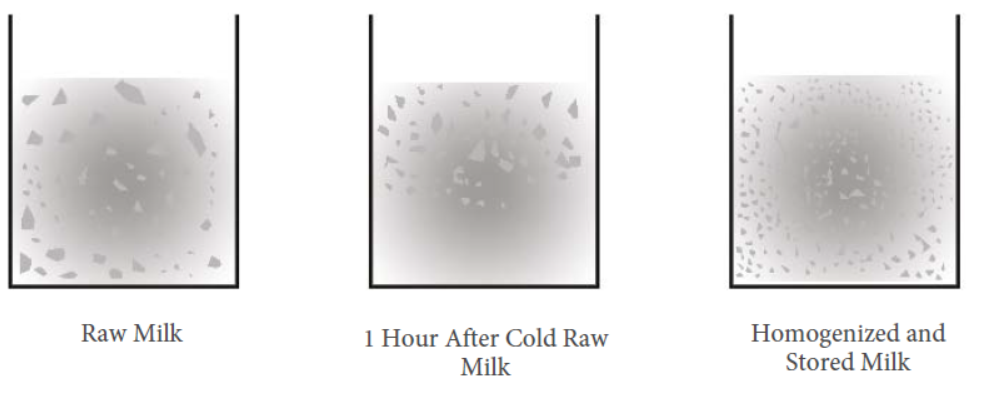

The homogenizers preserve the emulsion of milk intact for a long time. These devices divide the oil particles in milk emulsion into smaller pieces. Thus, the globules are prevented from going to the surface of the milk and agglomerating to form a creamy layer.

How Homogenizer Works?

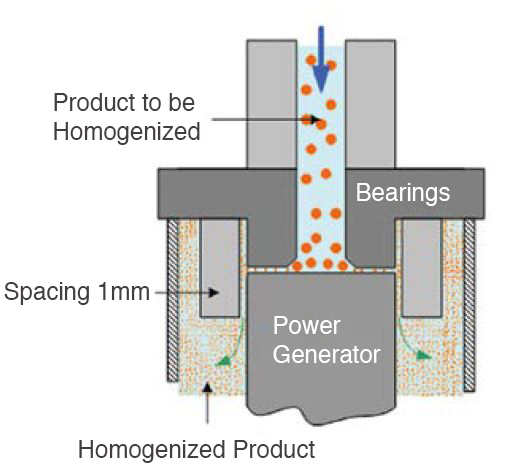

Homogenizers allow the fat globules to split into pieces less than 1 μm in diameter. This process takes place in the part of the homogenizer known as the homogenization head.

Homogenization Methods

Homogenization can be done in two ways, complete and partial.

Complete Homogenization

All milk is passed through the homogenizer. This method provides a good homogenization. But time and energy requirements are high.

Partial Homogenization

Cream is separated from milk to contain 12 - 20% fat. The separated cream is mixed with skim milk again to obtain a mixture containing 12% - 20% fat. This mixture is homogenized. Then, it is mixed with skim milk and adjusted according to the type of product.

Factors Affecting Homogenization

Ideal temperature for homogenization is 65-70 °C. Homogenization pressure is 50-70 C ° / 150-200 kg/cm2 for pasteurized milk.

Benefits of MIT Homogenizers

- Equal milk fat distribution

- Better tasting milk

- Partial increase in milk viscosity

- Easier to digest milk fat

- Whiter milk

- General quality improvement of milk

Call now Request a Quote Download Catalog

FOLLOW US ON FACEBOOK!

Be fan of our official Facebook fan page and development of the first to get your news!

Contents of Professional Service Package:

- Plate supply for every brand and model.

- Gasket supply for every brand and model.

- Revision and cleaning of plate heat exchanger.

- Fast and detailed cleaning of heat exchanger plates.

- Cleaning heat exchanger plates with special chemicals.

- Production and supply of every type of nut and pin.

- Delivery of heat exchanger operating like it is new.

- 7 days 24 hours service opportunity.