GEAR PUMPS

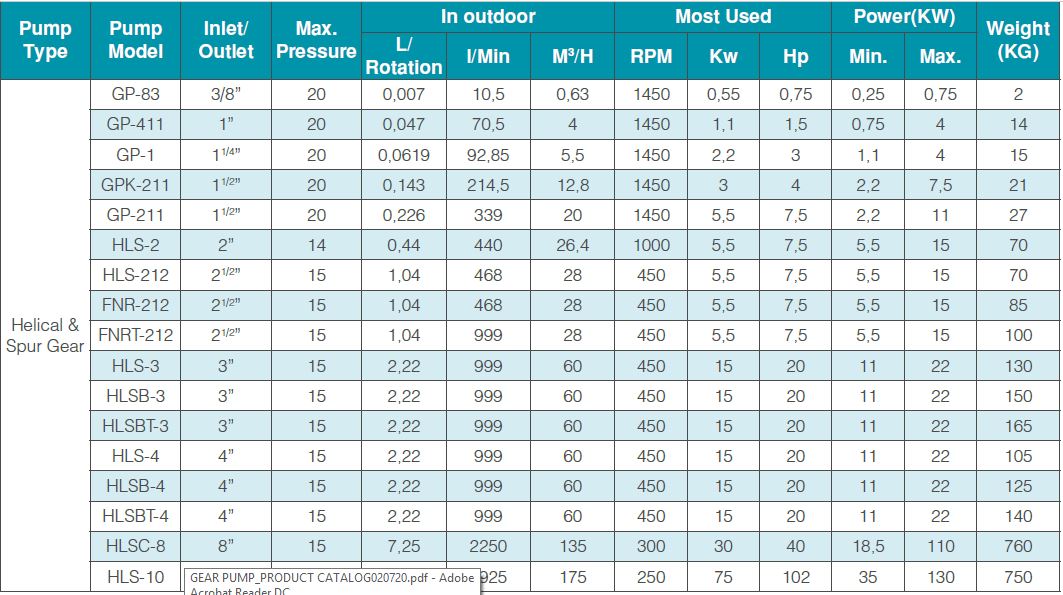

Helical And Spur - GEAR PUMPS

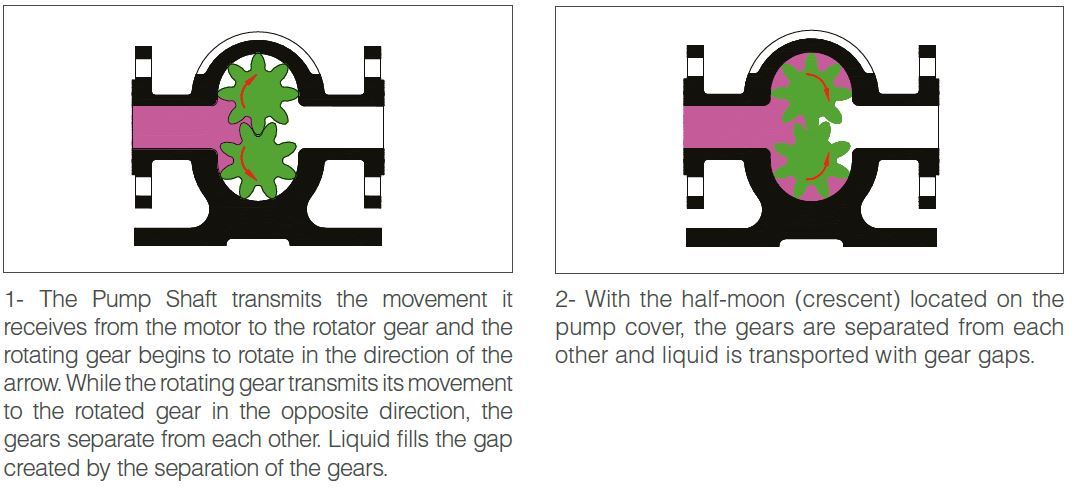

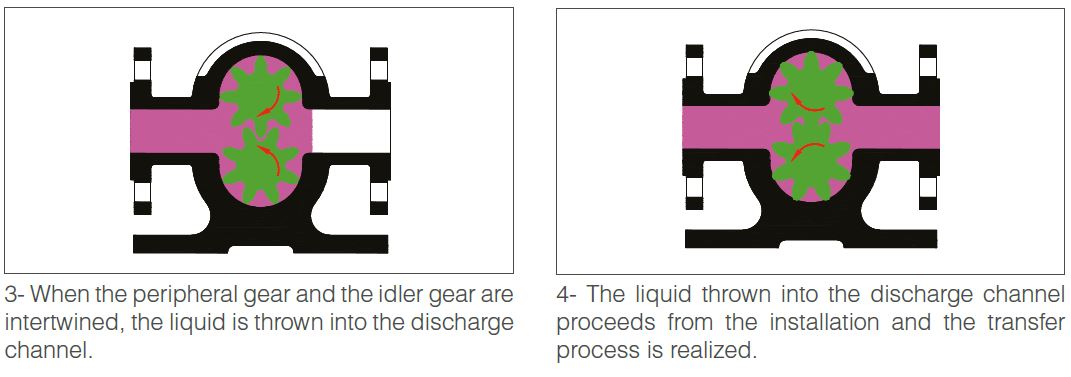

Helical & Spur gear pumps are positive displacement and consist of two moving parts. The pump shaft transmits the circular motion it receives from the motor to the gear on the shaft. While the rotator gear transmits its movement to the rotated gear in the opposite direction, the gears separate from each other and a vacuum is formed. Thanks to the vacuum formed, the pump draws a certain amount of liquid into it. The liquid drawn into the pump moves towards the discharge nozzle in the dental cavities. In the discharge nozzle, the gears intertwine and create pressure and allow the liquid to be thrown out. Pump; Each time the pump shaft rotates, it transfers fluid as much as its volume. Therefore, the capacity of the pump is directly proportional to its size and speed. The working principle of Helical & Spur gear pumps is shown schematically below.

Our helical & straight gear pumps are; Helical & straight gear pump, outboard ball helical gear pump, outboard ball & driven straight gear pump are gathered in three main groups. helical gear pumps operate with high efficiency in places where silent operation and continuous flow are desired. They have the ability to pass small and crushed particles in the liquid during transfer. Spur gear pumps work at high efficiency in the transfer of corrosive liquids, non-lubricating liquids and high temperature liquids in the places where medium pressure is required, externally ball and externally ball & driven helical gear pumps.

FOLLOW US ON FACEBOOK!

Be fan of our official Facebook fan page and development of the first to get your news!

Contents of Professional Service Package:

- Plate supply for every brand and model.

- Gasket supply for every brand and model.

- Revision and cleaning of plate heat exchanger.

- Fast and detailed cleaning of heat exchanger plates.

- Cleaning heat exchanger plates with special chemicals.

- Production and supply of every type of nut and pin.

- Delivery of heat exchanger operating like it is new.

- 7 days 24 hours service opportunity.