BOILER SYSTEMS

Solid Fuel Fired Three-Pass Automated Loaded (Stoker) Room Heater

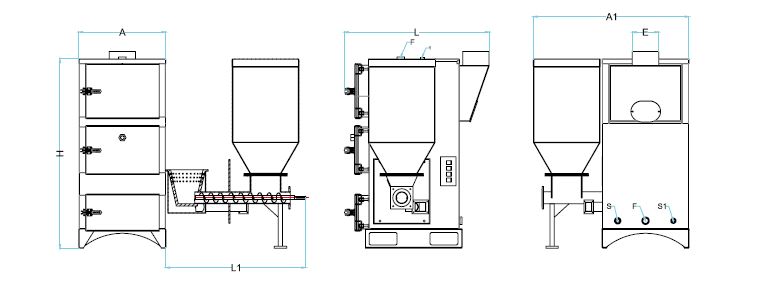

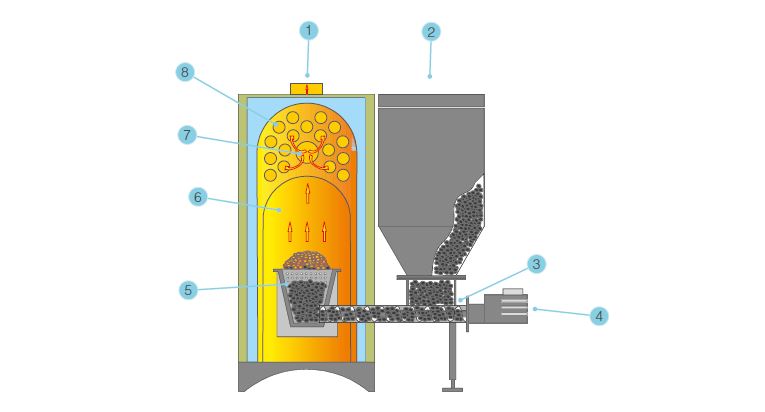

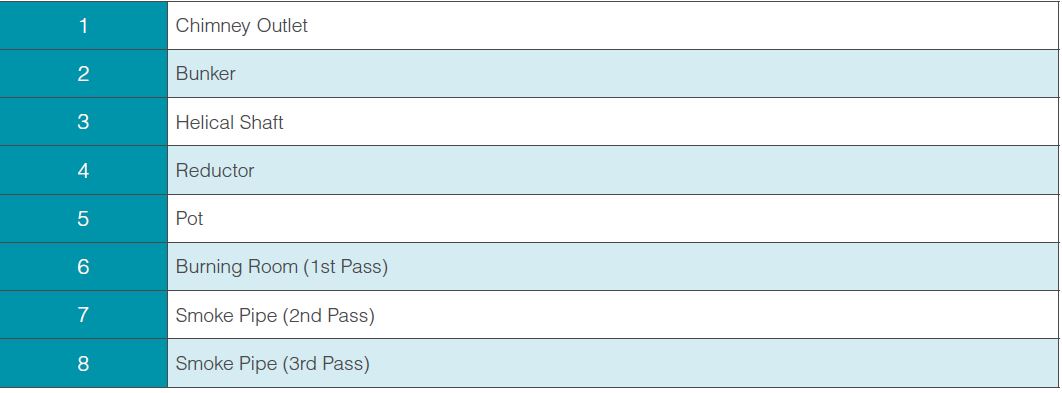

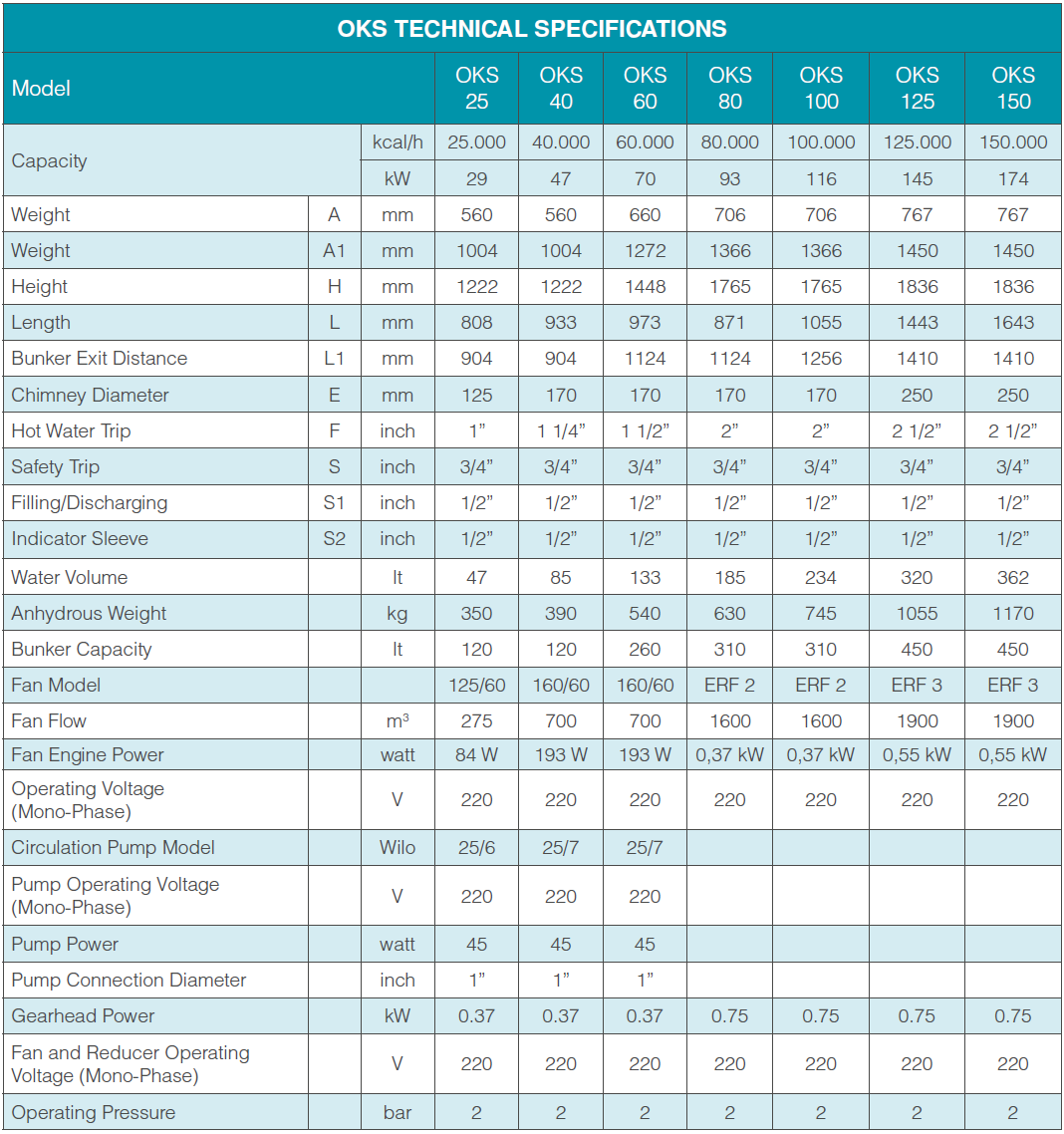

OKS Series; Solid fueled automated loaded room heaters are manufactured as semicylindrical and three-pass systems. 7 different types of production are made within the range of 25.000 kcal/h (29 kW) to 15,000 kcal/h (174 kW). Since the whole fuel is contacted with fan-controlled combustion system, the rate of unburned coal is low. Thanks to its three-pass design, it is designed in a way to burn fuels such as low-calorie domestic coal and wood in a highly efficient and environmentalist way. It allows maximum heat transfer and fuel saving by distributing by hand heat equally. While fuel loading is performed below via spiral thanks to automated fuel loading system, burning continues above, passage of smoke from spiral pipe to bunker is prevented due to special design of spiral loading system and an efficient combustion is ensured. At the same time, fuel consumption is reduced since thee are no errors or overloading resulting from incomplete burning errors.

Features

- High combustion efficiency up to 82%.

- Compatible to burning of nut coal at 10-25 mm sizes.

- Fuel loading, ash disposal and cleaning easiness with three different cover design.

- Adjustable caps with custom-designed cover handle and hinge structure.

- Combustion safety and fume resistance with locking lid and combustion safety.

- Specially designed chrome alloy casting ladle.

- Low gas emission values with eco-friendly design.

- Protection against all kinds of outer effect with steel construction in prismatic structure.

- Coating with electrostatic power paint on galvanized sheet.

- Standard operating pressure 2 bars.

- Semicircular boiler body.

- Ease of maintenance with detachable bunker.

- Key allowing forward-backward movement above reduction gear for coal jammings.

- Window type flame crushers in smoke pipes (turbulator).

- Frequency-controlled, energy-efficient circulation pumps.

- Use of 3.1 certificated boiler tube compatible with 10217-2 norm.

- Common service network.

- State-of-the-art manufacturing techniques.

- Compliance with National and International norms.

FOLLOW US ON FACEBOOK!

Be fan of our official Facebook fan page and development of the first to get your news!

Contents of Professional Service Package:

- Plate supply for every brand and model.

- Gasket supply for every brand and model.

- Revision and cleaning of plate heat exchanger.

- Fast and detailed cleaning of heat exchanger plates.

- Cleaning heat exchanger plates with special chemicals.

- Production and supply of every type of nut and pin.

- Delivery of heat exchanger operating like it is new.

- 7 days 24 hours service opportunity.